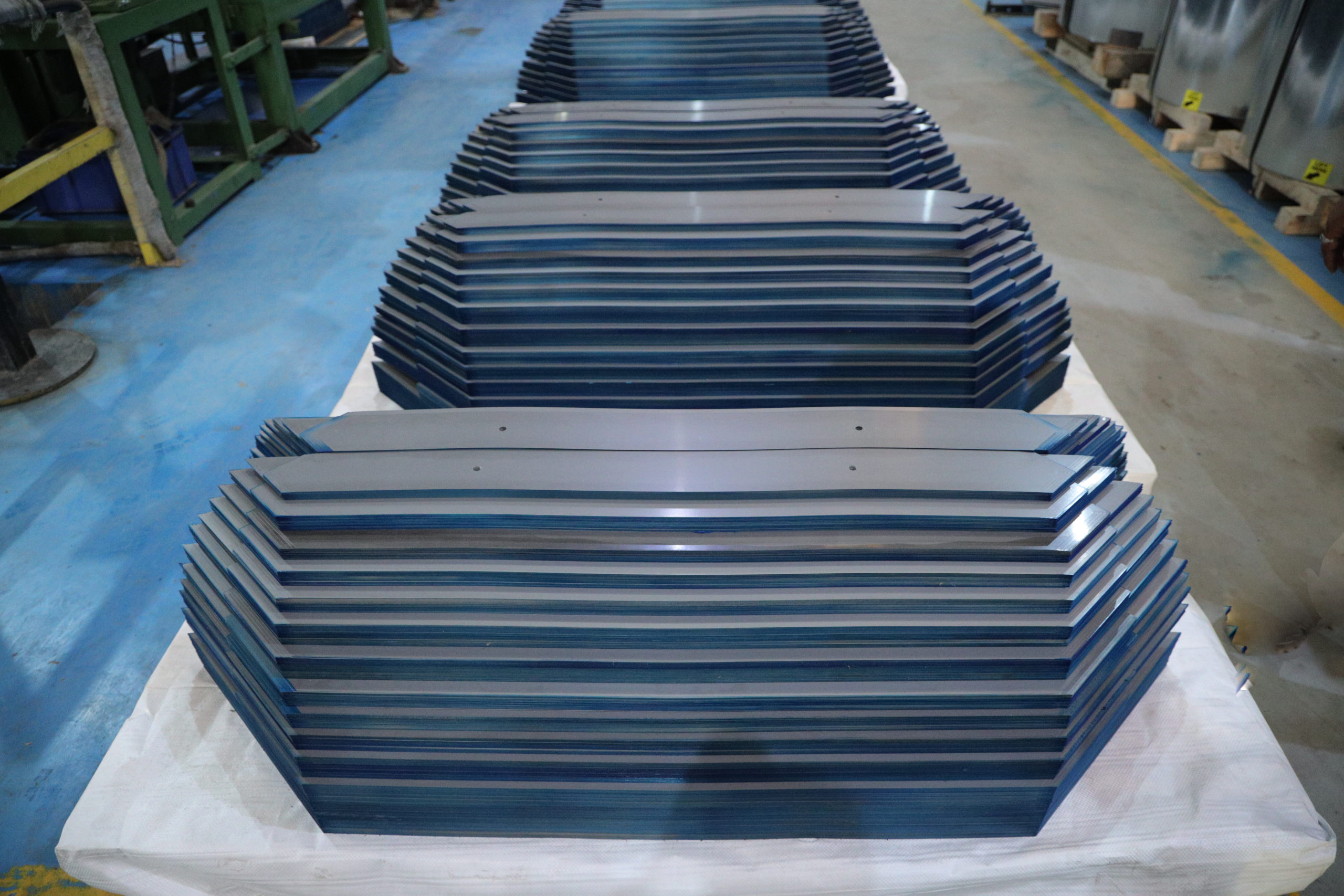

Transformer Core Lamination

Key Features of Transformer Core Lamination

Material

CRGO (Cold Rolled Grain Oriented Electrical Steel) – Prime Grade

Thickness Options

0.23 mm, 0.27 mm, 0.30 mm

Lamination Types

Mitred (45° angle), Rectangular (90° corners), Step-lap, Multi-step

Core Shapes

E&I, C, L, U, Circular (custom shapes available)

Slit Coil Width

Custom widths from 20 mm to 1000 mm

Lamination Length

Up to 1600 mm (or customized based on transformer design)

Burr Height

< 0.02 mm (Precision-controlled for reduced loss)

Coating Type

C5/C6 inorganic insulation coating (as per IEC standards)

Stacking Tolerance

± 0.2 mm

Packaging

Anti-rust paper wrap, wooden pallets/crates, coil banding

Why Choose Us?

25+ Years of Experience

Trusted by top transformer manufacturers across India

In-House Slitting & Cutting

Full control over quality and turnaround time

Technical Expertise

Support in selecting right grade and configuration

Consistent Quality

Strict Quality Check at every stage of manufacturing

Scalable Capacity

From small batch orders to bulk production

Commitment to Efficiency

Every lamination is designed to minimize energy loss

Get in Touch

Frequently Asked Questions

What materials do you use for transformer core laminations?

What thickness options are available?

What lamination types do you offer?

Can you make custom core shapes?

What are your slit coil width and lamination length options?

How precise are your laminations?

What coating do you use?

How do you package laminations?

Do you supply both small and bulk orders?

Do you export internationally?

Yes, we supply laminations to both Indian and overseas transformer manufacturers.

Our Latest Blog

In transformer manufacturing, precision is not just a quality benchmark—it is a cost-control strategy. Every component …

As power infrastructure expands worldwide, the demand for energy-efficient transformers continues to grow. At the heart …

Transformer laminations are the silent drivers of transformer efficiency, reliability, and lifespan. Forming the magnetic core …